Home > Product > Food Mixer / Stainless Steel Industrial Mixer (1HP 2HP, AC DC 110V, 220V, 380V)MG-236/237/238

-

Product Information

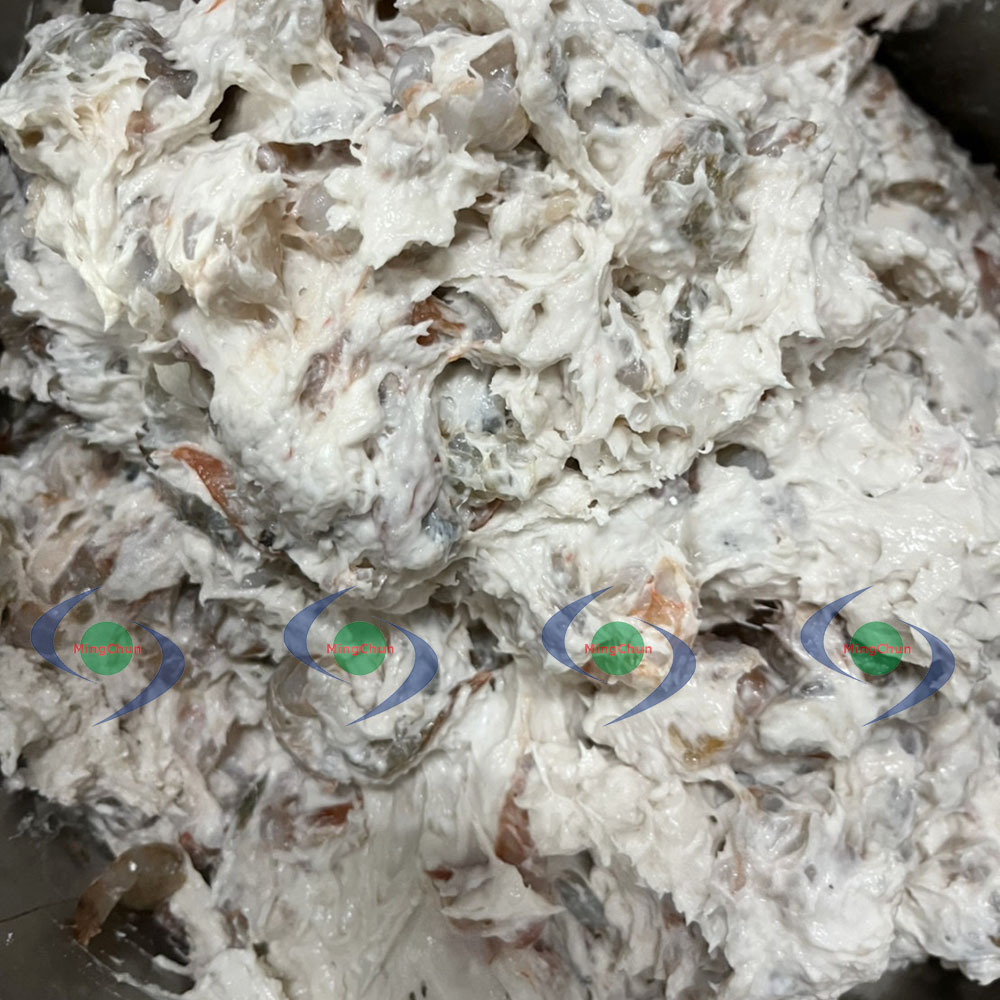

Food-grade mixers primarily allow for the thorough mixing of two or more ingredients, enhancing the consistency beyond what manual mixing achieves while increasing production capacity. They can also achieve uniform mixing when used for animal feed, fertilizers, and pesticide powders.

For ingredient mixing, we offer three different size specifications to meet the mechanical requirements based on the capacity needed and the ingredients you are working with.

Please refer to the chart for details.

Model

MG-236

MG-237

MG-238

Dimension (L x W x H)

940 x 780 x 1100mm

1240x 780 x 1100mm

1530 x 780 x 1100mm

Voltage / Power

110V,220V, 380V / 1HP

220V, 380V / 1HP

220V, 380V / 2HP

Weight

120kg

128kg

155kg

Volume

50L/30kg

130L/60KG

150L/90KG

Function

Mix

Capacity

100-200kg per hour.

It depends actual ingredients and sizes.

200-400 kg per hour.

It depends actual ingredients and sizes.

300-500 kg per hour.

It depends actual ingredients and sizes.

"Daily necessities for increased productivity, let Ming chun Food Machinery provide you with a more efficient helping hand. Ming chun goodbye to the laborious and time-consuming hand cutting. Ming chun Machinery is here to solve your processing problems."

"Using and Maintenance Guidelines:

- Operate the processing machine in good lighting conditions.

- After each use, ensure thorough cleaning and remove any residual materials.

- Do not put metal, stones, or sharp objects during processing, as this can cause blade damage or cracking.

- Before starting, make sure to correctly install the required cutter for proper cutting.

- If unusual operating noise is detected during use, immediately stop operation, turn off the power, clear any obstructions, and then turn on to use.

- Periodically check all screws for loosening after a period of time use and tighten them as necessary.

- Store the machine in a well-ventilated area if it is not used for an extended period to prevent humidity.

- Do not operate the machine for a long time to prevent motor overheating to extend its life span."

"Machine Purchase Warranty:

- If machines damage or defects caused during machinery transportation, please contact us immediately for assistance. Do not accept the delivery until you have taken photos and informed our company. Our company will communicate with the logistics company to confirm responsibility. Once notified by our company, you may proceed to take photos of the damaged machine. Any logistics and machinery repair costs incurred will be covered by our company.

- Situations caused by human factors, accidents, improper use, self-modification of machine parts, natural disasters, or electrical issues are not covered by the warranty.

- The warranty period is one year and applies only to the main machinery. Product accessories, attachments, or other consumable parts are not covered by the warranty.

- For operating and processing issues caused by the company's machinery, lifetime service will be provided free of charge."

"We supply food processing machines for use in commercial kitchens that are easy to clean, user-friendly, and safe. They operate with high efficiency, offering fast cutting speeds, and result in food that is visually appealing and with a glossy finish. Having a food processing machine optimizes time and labor costs."

"Ming chun Machinery has a team of professionals to assist you in finding the right processing machine to meet your needs, solving your processing requirements, and improving work efficiency and productivity satisfaction."

-

Q&A